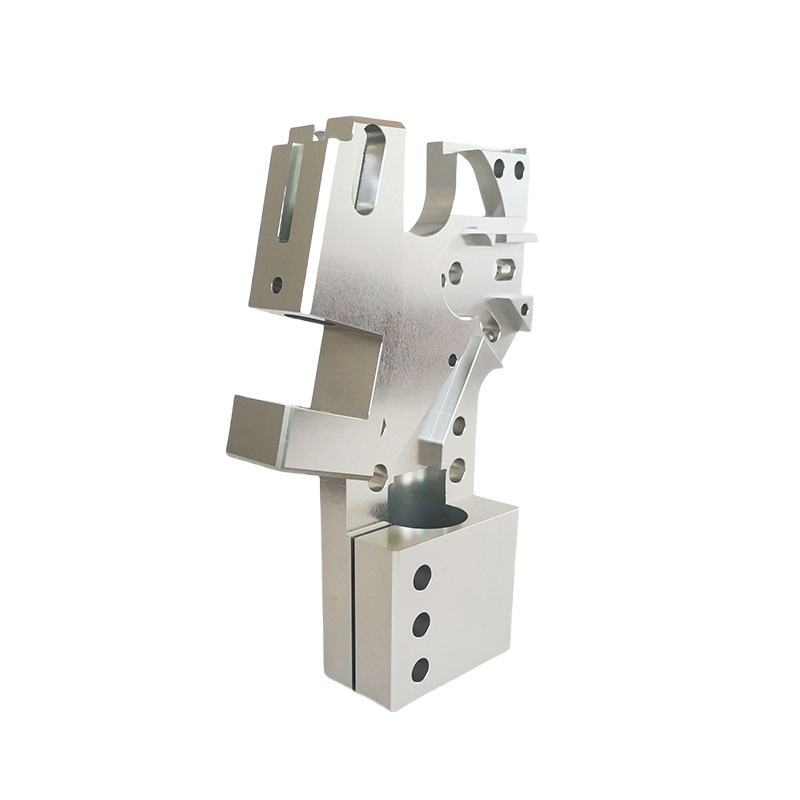

In high-end manufacturing, the value of a stainless steel precision part lies not only in its stringent dimensional accuracy and material properties, but also increasingly in its surface finish.

- +86-13790250376+86-13537185391

- 13790250376@163.com

- No.1 Xintai 1st Street, Dalang Town, Dongguan City